How Laser Thermometers Are Revolutionizing Temperature Measurement

Temperature measurement is a critical aspect of various industries, from food production to automotive manufacturing. Traditional thermometers are effective but have limitations in terms of speed, accuracy, and convenience. However, with the advent of laser thermometers, a new era of temperature measurement has emerged. Laser thermometers are revolutionizing the way we measure temperature, offering a wide range of benefits that were previously unattainable. In this article, we will explore how laser thermometers are changing the game and why they are a must-have tool for any industry that relies on accurate temperature readings.

The Basics of Laser Thermometers

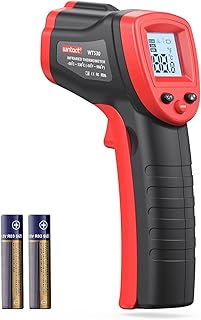

Laser thermometers, also known as infrared thermometers, work based on the principle of detecting infrared energy emitted by an object. This energy is converted into a temperature reading, allowing for non-contact temperature measurement. Unlike traditional thermometers that require physical contact with the object being measured, laser thermometers can accurately measure temperature from a distance. This feature is particularly useful in situations where contact measurement is not feasible or safe, such as in high-temperature environments or when measuring moving objects.

Benefits of Laser Thermometers

There are several key benefits of using laser thermometers for temperature measurement:

1. Speed and Accuracy

Laser thermometers provide instant temperature readings, allowing for quick and accurate measurements. This is especially important in industries where temperature fluctuations can have a significant impact on the quality of the products being manufactured. With laser thermometers, operators can quickly identify temperature variations and take corrective actions to ensure product quality and consistency.

2. Non-contact Measurement

One of the most significant advantages of laser thermometers is their non-contact measurement capability. This feature allows operators to measure temperature from a safe distance, reducing the risk of injury or contamination. Non-contact measurement is particularly useful in industries such as food production, where maintaining sanitary conditions is crucial.

People Also Look For:

- Infrared Thermometer Cooking Digital Temperature Gun -58℉-1076℉ Non-Contact Laser Thermometer for Cooking/Pizza/Oven/Refrigera...

- ThermoPro TP30 Infrared Thermometer Gun, Laser Thermometer for Cooking, Pizza Oven, Griddle, Engine, HVAC, Laser Temperature Gun w...

- Laser Thermometer Cooking Gun Non Human Laser Infrared Temperature Gun -58°F ~ 752°F, Non-Contact Adjustable Emissivity IR Therm...

- Non Contact Industrial Infrared Digital Thermometer Gun -50~550C temperature range

- Bosch infrared thermometer UniversalTemp (-30°C...+500°C, easy and precise measurement, 3 predefined material groups, in E-Comme...

3. Versatility

Laser thermometers can be used to measure temperature across a wide range of applications, from industrial processes to HVAC systems. They can accurately measure temperature in hard-to-reach areas or hazardous environments, providing operators with valuable insights into temperature variations that could impact product quality or equipment performance.

4. Portability

Many laser thermometers are compact and lightweight, making them easy to carry around and use in various locations. Their portability makes them an ideal tool for field technicians, inspectors, and maintenance personnel who need to measure temperature on the go. With a laser thermometer, operators can quickly assess temperature levels without the need for bulky equipment or lengthy setup procedures.

5. Energy Efficiency

By enabling quick and accurate temperature measurements, laser thermometers contribute to energy efficiency in industrial processes. Operators can identify and address temperature inefficiencies promptly, optimizing energy usage and reducing waste. This not only helps companies save on energy costs but also minimizes their environmental footprint.

Applications of Laser Thermometers

Laser thermometers are widely used across various industries for temperature measurement. Some common applications include:

1. Food Safety

In the food industry, laser thermometers are used to monitor food storage temperatures, ensuring compliance with food safety regulations. They are also used to measure the temperature of cooking equipment to prevent undercooking or overcooking of food products.

2. Automotive

In the automotive industry, laser thermometers are used to measure the temperature of engine components, brake systems, and other critical parts. They help identify overheating issues and prevent equipment failures, contributing to vehicle safety and performance.

3. HVAC

In the HVAC industry, laser thermometers are used to diagnose heating and cooling system problems by measuring temperature differentials across components. They help HVAC technicians identify inefficiencies and optimize system performance, leading to energy savings and improved comfort for building occupants.

4. Industrial Processes

In industrial settings, laser thermometers are used to monitor temperature during manufacturing processes, ensuring product quality and consistency. They are also used to detect hot spots in electrical systems, preventing equipment damage and reducing the risk of fire hazards.

Conclusion

Laser thermometers have revolutionized temperature measurement by offering speed, accuracy, convenience, and versatility. Their non-contact measurement capability makes them an essential tool for industries that require precise temperature readings in challenging environments. As technology continues to advance, laser thermometers will likely play an increasingly important role in ensuring product quality, safety, and efficiency across a wide range of applications.